If you use hot melt adhesive, then you understand how time-consuming hot melt clean up can be. Manufacturers recommend a long list of cleaning tasks every 8 hours, 40 hours, and 160 hours in addition to daily maintenance and inspections. You have to clean hoses, spray guns, manifolds, nozzles, filters, and flush the entire system.

Or… you could choose a better approach.

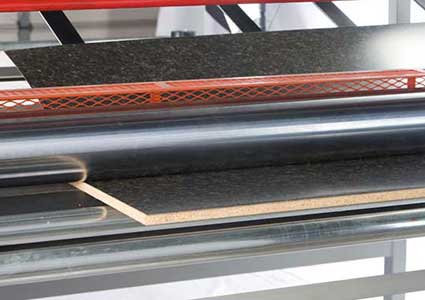

HMT Manufacturing’s Advantage Laminating System uses a unique holt melt film adhesive that virtually eliminates messes and the corresponding cleanup process. The adhesive process is faster, cleaner, more consistent, and takes place in a healthier working environment vs. traditional hot melt procedures.

Why would you use anything else?

Seeing is believing, so we invite you to watch the following video and let us provide you with a sample of your material run through our equipment so you can see for yourself.