Why does it matter if an adhesive contains water? Moisture can impact materials. When adhesive cures (dries), the water in an adhesive must evaporate. For non-permeable materials such as metal, there is no where for the water to go when curing. For permeable materials such as paper, water distorts the material by getting into cells, causing wrinkles and warping.

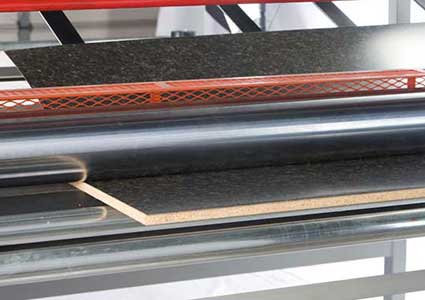

To cure, water-based adhesives require time and space. Simply put, they must sit for an extended period of time until dry. In some cases, dryers are employed to expedite the cure process. Dryers cost money. Running the dryers costs money. Square footage costs money. And, time costs money. All of those costs are eliminated when using hot melt film adhesive from HMT Manufacturing.

Water-based adhesives require extensive clean up. Hot melt adhesive film does not.

Any water used in the cleanup process of a water-based adhesive is subject to wastewater disposal regulations.

Adhesives are often sold by the pound. Water-based adhesives are often 30%-40% water. Think about what that does to your cost and shipping.

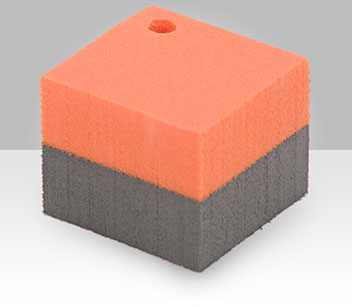

Clearly, water-free adhesive is advantageous. To see a sample of the wide range of materials that have been bonded by HMT’s Advantage hot melt adhesive, be sure to visit our online Lamination Gallery. Better yet, let us provide a sample of your materials bonded on the Advantage Laminating System — request a sample now.