Consistent area coverage might be the single most important attribute of an adhesive system. Uneven adhesive coverage is the leading cause of bond failure. Spray adhesives are often applied too heavily in some areas while others receive little to no coverage. A smart alternative: hot melt film adhesive.

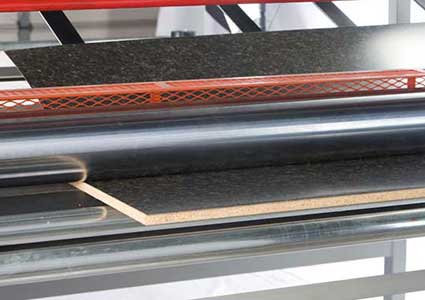

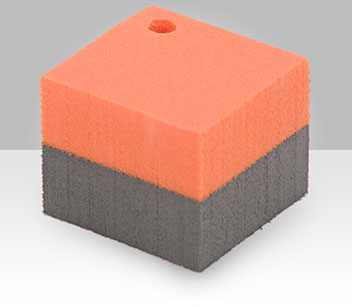

Hot melt film adhesive is a thin, non-shrinking, fabric-like sheet of adhesive with uniform thickness. That uniformity guarantees consistent area coverage. The film adhesive is applied between the laminate and substrate. No voids or hollows under your laminate material. No excess spray or spills in your facility. And, finished panels are ready for immediate fabrication! Rather than waiting for glue to cure/dry, bonded materials exit our lamination machinery ready to use. You can cut, drill, route, and handle them.

Want to see it for yourself? We can run samples of your materials through our equipment, using our film adhesive, and ship them to you so you can see it, touch it, inspect it, and believe it. Request your sample here.