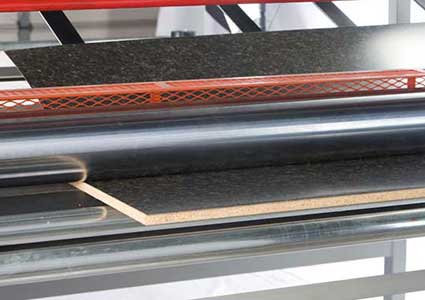

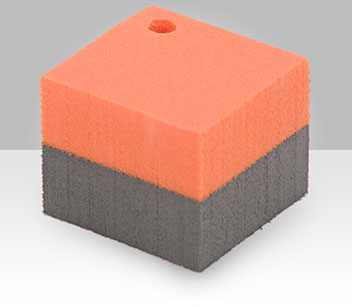

HMT’s Advantage Laminating System excels at bonding multiple substrates. Whether you use our standard laminating equipment or our custom lamination machinery solutions, you will enjoy all the benefits of using hot melt film adhesive. Benefits include:

1. No Wait Time

Laminated output is ready for immediate use. There is zero cure time.

2. Flexible Glue

Our film adhesive remains flexible after application. That means you can store laminated output in roll format, and can run it through the lamination equipment again if you need to apply additional substrates.

3. Consistent Quality

Because our adhesive comes in film format, the perfect amount of adhesive is applied throughout the bonded area, evenly. No waste, no mess, and no quality defects.

4. Healthy Working Environment

Advantage hot melt film adhesives use no solvents, no toxins, no VOC’s. When you work with Advantage hot melt adhesive, you avoid the harmful fumes and airborne particles produced by sprays. And, your workplace will be cleaner (no glue spray on walls, tables, floors, etc).

To bond multiple substrates, you can choose from many methods:

- Use one machine, laminate two materials, manually bring the output to the infeed, and apply another layer.

- Run multiple machines in sequence.

- Run multiple machines, side-by-side, using a board flipper to transfer output from one machine to another.

- Let us build a custom laminating machine for you. We have built custom machines that do more than 2 layers at a time. Tell us your needs, and we will provide a complete proposal for your review.

Let us show you the result of bonding your multiple substrates using our adhesive on our equipment. Send us samples of your materials, and we will bond them and return the finished samples to you free of charge so you may inspect their quality and strength. Request a sample today.