Adhering fabric to substrates can be challenging. Most glues bleed through the fabric and create stains and wrinkles, cause unwanted shrinkage or expansion, and force the flexible fabric to become rigid. Except one adhesive . . .

HMT’s Advantage hot melt adhesive film is different. It is similar to material used in glue guns but is cast in the form of a fabric. At room temperature, this fabric-like material is not sticky to the touch.

HMT’s Advantage hot melt adhesive film is different. It is similar to material used in glue guns but is cast in the form of a fabric. At room temperature, this fabric-like material is not sticky to the touch.

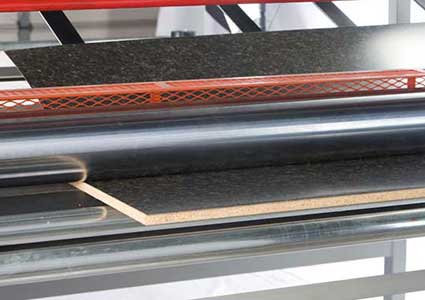

When using our Advantage Laminator equipment, only the adhesive is briefly exposed to 350 degree (Fahrenheit) heat which activates the film adhesive. The fabric and substrate materials remain at room temperature. This unique system allows lamination of very delicate materials.

Material is securely and evenly bonded to a substrate, instantly. The finished product is ready for immediate fabrication.

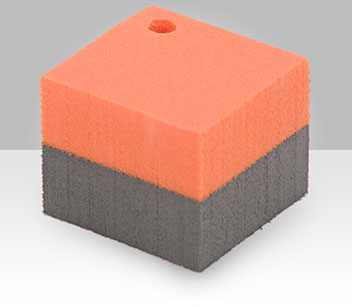

Advantage hot melt adhesive adheres to the surface of the fabric and the substrate — it doesn’t bleed through the materials but it does provide 100% uniform coverage. No wrinkles, no stains, no water, no shrinking. This adhesive gives laminated materials a “soft hand,” remaining pliable and flexible.

An optional roll stock feed attachment allows continuous feeding of exceptionally long lengths of fabric material.

Seeing is believing. Request a sample of your fabric material bonded with our adhesive so you can see, touch, and inspect the quality of HMT Advantage hot melt adhesive film.