Hot Melt Film

Hot melt film — similar to the glue used in hot melt glue guns, but in the form of fabric — is placed between a material and a substrate to laminate them into one. HMT offers a variety of hot melt … Continue reading

Reducing Weight by Adhering Finish Material to Honeycomb

Reducing weight of components can significantly improve your product. Reduced weight can lower shipping costs, make your product easier to carry, or reduce the amount of energy required to move the component (aircraft, vehicles, etc). But how do you reduce … Continue reading

Hot Melt Machine

Rather than buy a hot melt machine, you can invest in a clean machine that uses pre-cast adhesive film activated by infrared heat. Traditional hot melt machines are messy, wasteful, emit fumes, and require extensive cure times. Our Advantage Laminating … Continue reading

Environmentally Responsible Adhesive that is Better for Our Planet

Seems every company these days uses the word “green” in their advertising but they don’t back it up. At HMT Manufacturing, our adhesives have always been free of volatile organic compounds (VOC’s) and solvents. 100% of our hot melt products … Continue reading

Adhesive that’s Easy to Handle

HMT’s hot melt adhesive film is easy to handle. In its raw form, the adhesive film can be held in your hand. It won’t stick to your hands despite the fact that it is 100% adhesive. “100% adhesive” means there … Continue reading

Consistent Area Coverage for Adhesives

Consistent area coverage might be the single most important attribute of an adhesive system. Uneven adhesive coverage is the leading cause of bond failure. Spray adhesives are often applied too heavily in some areas while others receive little to no … Continue reading

Market Spotlight: Aircraft Interiors

HMT’s Advantage hot melt film adhesive is used in aircraft interiors. Our lightweight, flexible, flame-retardant adhesive bonds materials used in aircraft ceilings, aircraft wall liners, aircraft upholstery, and insulating materials. Because the adhesive remains flexible after application, bonded materials can … Continue reading

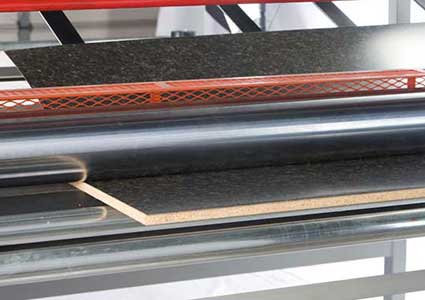

Continuous Fusing

HMT’s Advantage Laminating System employs continuous fusing. Continuous fusing allows non-stop production. Our rolls of adhesive are 500′ long and can be spliced together, allowing unlimited lengths and output. Of course, our machines can also be used for smaller, on-demand … Continue reading

Bonding Multiple Substrates

HMT’s Advantage Laminating System excels at bonding multiple substrates. Whether you use our standard laminating equipment or our custom lamination machinery solutions, you will enjoy all the benefits of using hot melt film adhesive. Benefits include: 1. No Wait Time … Continue reading

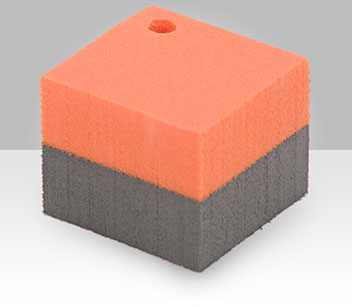

Bonding Packaging Materials

Advantage hot melt film adhesive is used to bond packaging materials such as foams, corrugated products, felts, fabrics, and plastics. Some customers bond liner materials (felt, fabric, etc) to packaging materials to protect products from scratches during shipping. Others have … Continue reading