To err is human. If you rely on humans to manually apply adhesive to substrates, there will be voids, bubbles, and uneven adhesive coverage. If you catch them, you will have to replace the laminated panels that failed QC inspection. If you don’t catch them, you will ship poor quality product, risking your company’s reputation and inviting warranty claims.

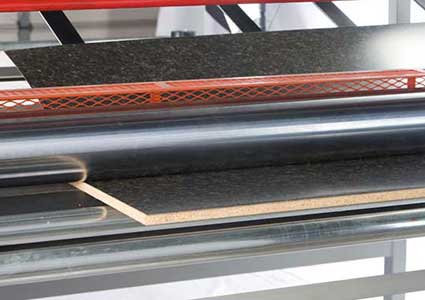

To avoid uneven adhesive coverage, consider a hot melt adhesive film solution. HMT’s Advantage Laminating System provides even, consistent adhesive coverage. It also reduces cleanup, cure time, and is solvent-free. Our customers are producing laminated output up to 10 times faster than manual methods, at up to 50% lower cost.

Seeing is believing. Let us run a sample of your material through our equipment so you can see the even adhesive coverage yourself. To request a sample, contact us here.